As professionals in the poultry industry, we understand that maintaining flock health is a critical aspect of our work. Central to this is ensuring the quality and safety of eggs produced in our hatcheries.

This means we need to correctly distinguish between a live egg, a dead egg, and a contaminated egg. Misidentification can lead to a slew of problems, ranging from a breakout of infection to a substantial loss of chicks. In this article, we will delve into how to identify and remove non-viable eggs before incubation through the use of innovative technology, LaserLife®.

- 1 Understanding the essence of egg safety

- 2 Making use of LaserLife® technology

- 3 Examining equipment features

- 4 The importance of reliable egg sorting

- 5 Exploring other products in the range

- 6 Seeking additional information ?

- 7 Decoding fresh, dead, and contaminated eggs: a detailed breakout analysis

- 8 Utilizing LaserLife® technology for efficient egg sorting

- 9 LaserLife®: enhancing efficiency and record-keeping in hatcheries

- 10 The imperative role of accurate egg sorting

Understanding the essence of egg safety

In poultry production, the health status of an egg is critical. It is the first step in maintaining the safety of the flock and ensuring optimal production rates. It is here that we encounter the need to differentiate between live eggs, dead eggs, and contaminated eggs.

A live egg is one that contains a viable embryo, ready for incubation and hatching. Dead eggs, on the other hand, contain embryos that have ceased developing. These can often be identified through a process called “candling”, which involves shining a light through the shell of an egg to observe the embryo inside. However, the most problematic eggs are the contaminated ones. These are eggs that have been infiltrated by harmful substances or organisms, such as Salmonella, which can lead to widespread infection among the flock and pose a risk to human health.

Making use of LaserLife® technology

LaserLife® technology offers a unique and efficient solution to the challenge of identifying and sorting eggs. Through a dual sensor analysis, this technology can categorize each egg as either live, dead, contaminated, or clear.

First, using careful laser analysis, the technology examines the refraction patterns of the eggs to determine their status. The heat emission from fertile eggs is then analyzed, along with an infra-red scan.

The ability to categorize eggs in this way enhances biosecurity at the site. It allows for the removal of non-viable eggs before they reach the incubation stage, thereby preventing potential outbreaks of infection and ensuring the safety and health of the flock.

Examining equipment features

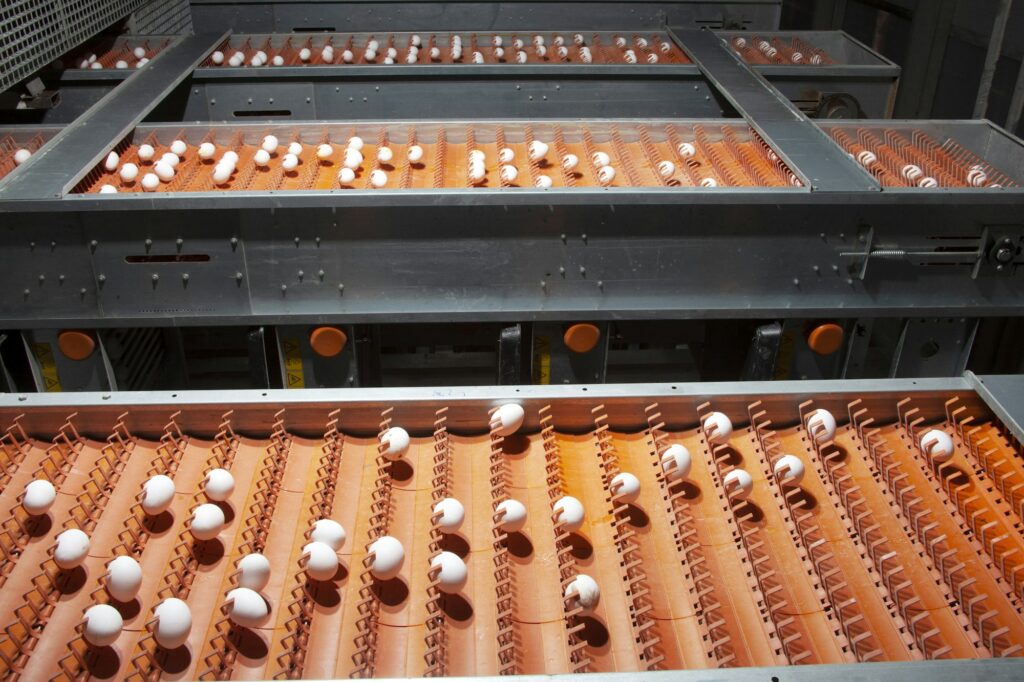

LaserLife® comes with several features designed to enhance efficiency and adaptability. It can process up to 100,000 eggs per hour, making it suitable for hatcheries of various sizes.

The system is also versatile, adaptable to different crate sizes, and comes with a data collection system in place. This feature allows for accurate record-keeping and tracking, aiding in maintaining the health and safety of the flock.

The importance of reliable egg sorting

Misidentifying an egg’s status can lead to a breakout of infection among a flock. Contaminated eggs can result in late embryo mortality, reduce hatchability, and lead to poor chick quality.

By using LaserLife® technology for egg sorting, hatcheries can improve their hatchability rates by between 0.5 and 1%. More importantly, chicks that hatch from eggs sorted using this technology pose a lower bacteriological challenge at hatch. This leads to an improvement in the overall chick quality index and better health status for the chicks.

Exploring other products in the range

In addition to LaserLife®, there are other products available in the same range. These include the Chick Counter and the Tray Unloader. The Chick Counter is designed to count the number of chicks hatched in a particular batch, while the Tray Unloader helps in efficiently unloading the hatched chicks.

Seeking additional information ?

We understand the critical role that professional-grade equipment and knowledge play in maintaining the health and safety of our flocks. To this end, we encourage you to learn more about egg candling and how LaserLife® technology can be integrated into your operations.

Decoding fresh, dead, and contaminated eggs: a detailed breakout analysis

Understanding the difference between a fresh egg, a dead egg, and a contaminated egg is crucial for maintaining flock health. A fresh egg houses a viable embryo, prepared for incubation and subsequent hatching. Dead eggs, in contrast, contain embryos which have stopped developing. Usually, these can be identified through candling, a common process where light is shone through the egg shell to examine the contents.

However, the problematic kinds are the contaminated eggs. These are infiltrated by harmful substances or microorganisms such as Salmonella, posing a considerable risk to both the breeder flock and human health. When handling eggs, it is crucial to identify these contaminants to prevent potential outbreaks in your flock.

Contaminated eggs are not always easy to spot, especially when the contamination is internal. An egg contaminated internally may appear normal from the outside but house harmful substances that could be fatal to the unhatched chicks. If these eggs are mistakenly incubated, they could cause a significant flock health crisis, leading to substantial economic loss.

A rotten egg is an extreme example of a contaminated egg, where the egg contents have spoiled due to bacterial activity. These eggs give off a strong foul smell and are easily identifiable. However, not all contaminated eggs reach this stage, making it crucial to have an effective egg analysis system in place.

Utilizing LaserLife® technology for efficient egg sorting

LaserLife® technology provides an innovative solution for distinguishing between fresh, dead, and contaminated eggs. This technology uses a dual sensor analysis for categorizing each egg based on its status.

The LaserLife® technology begins by examining the refraction patterns of the eggs using a laser. This analysis is complemented by a heat emission assessment from fertile eggs and an infrared scan. These examinations help categorize the eggs into live, dead, contaminated, or clear categories.

The advantage of this innovative technology is its contribution to maintaining biosecurity at the production site. It facilitates the removal of non-viable eggs before they reach the incubation stage, thus averting potential disease outbreaks and ensuring the safety and health of the breeder flock. The technology also helps keep the eggs at room temperature during the analysis, preventing any potential damage.

LaserLife®: enhancing efficiency and record-keeping in hatcheries

LaserLife® is equipped with various features to increase efficiency and versatility. It can process up to 100,000 eggs per hour, making it suitable for both small and large hatcheries. The system can adapt to different crate sizes and comes with a data collection feature for accurate record-keeping and tracking. This data can help in analyzing trends and identifying any potential problems in the breeder flock.

Accurate record-keeping is essential for maintaining food safety standards and ensuring the ongoing health of the flock. The data collected can provide valuable insights into the flock’s health status, egg production rates, and the efficiency of the sorting process.

The imperative role of accurate egg sorting

Ensuring the health and safety of a breeder flock depends heavily on accurate egg sorting. Misidentifying an egg’s status can cause an infection breakout among the flock, affecting the hatchability rate, chick quality, and overall flock health.

Utilizing LaserLife® technology for egg sorting can improve hatchability rates by 0.5 to 1%. More crucially, it significantly reduces the bacteriological challenge at hatch, leading to better chick quality and health status.

For additional information on efficient egg handling, the benefits of LaserLife® technology, and other products in the range, reach out to our experts today. Remember, maintaining the health and safety of your flock starts with accurately identifying the status of each egg.